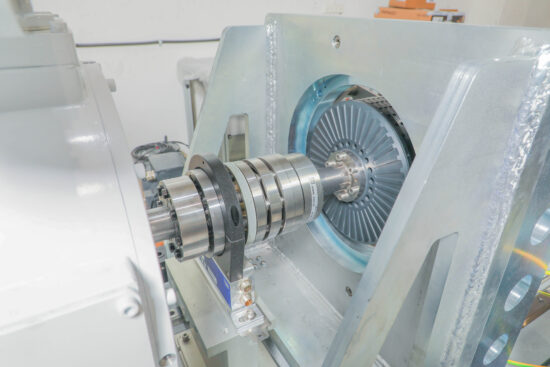

E-Motors for Industry, Aerospace, Logistics, Transportation, Testing Labs

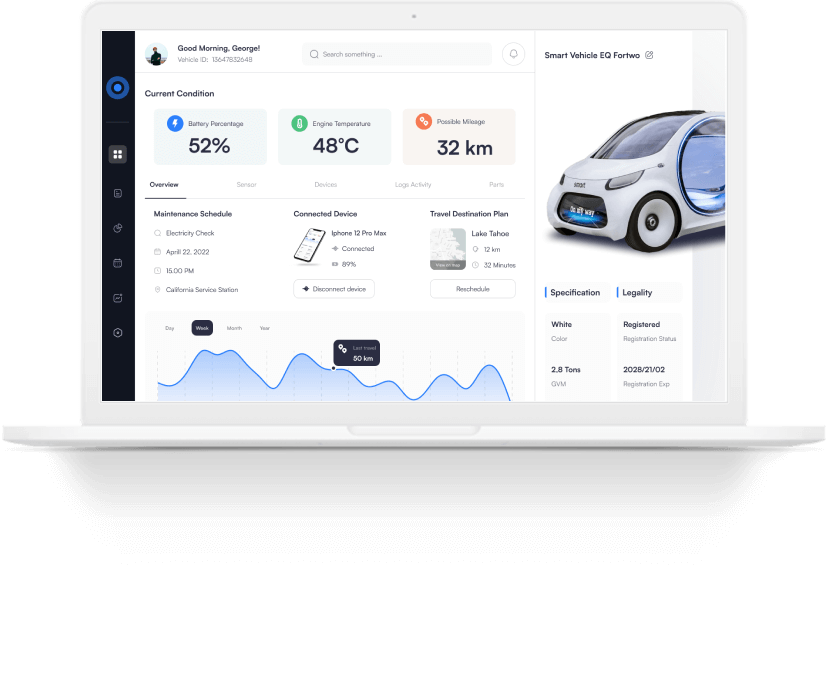

Mission-Critical Testing for High-Stakes Applications

In sectors where precision, safety, and durability are paramount — such as aerospace, industrial automation, logistics, and transportation — electric motors must perform flawlessly under demanding conditions. Whether for mission-critical aerospace components or high-efficiency conveyor systems, comprehensive motor testing is essential for quality assurance, compliance, and innovation. Motomea’s versatile testing platforms, including our Regenerative Dynamometer Systems (RDS) and patented IDS technology, empower manufacturers and test labs to simulate real-world load scenarios, capture dynamic performance data, and validate motor integrity with absolute confidence — ensuring that every motor meets the highest global standards.

Thank you for your submission! Your brochure is on the way!

Thank you for your submission! Your brochure is on the way!