Menu

- Home

- Products

- Dynamometers for All Types of Motors

- Dynamometers for EV & Traction Motors

- Dynamometers for Automotive Motors & Power Steering

- IEC-IEEE-CSA-IS Standards

- Mathematical Modeling – PI

- Gear Tester

- Powertrain

- Chassis Dynamometer

- Battery Testing & Simulation

- Bearing Tester

- Power Analyzer

- Transformer Tester

- Solutions

- Industries

- Success Stories

- Resources

- Company

- Home

- Products

- Dynamometers for All Types of Motors

- Dynamometers for EV & Traction Motors

- Dynamometers for Automotive Motors & Power Steering

- IEC-IEEE-CSA-IS Standards

- Mathematical Modeling – PI

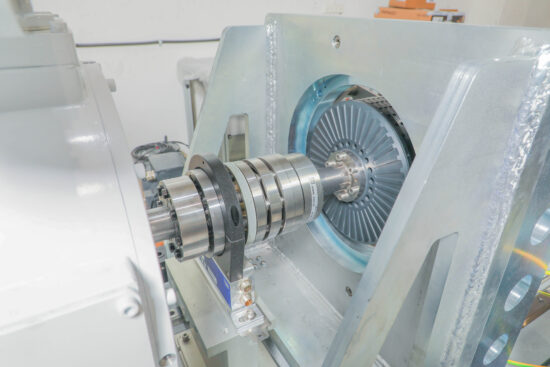

- Regenerative Dynamometer

- Gear Tester

- Powertrain

- Chassis Dynamometer

- Battery Testing & Simulation

- Bearing Tester

- Power Analyzer

- Transformer Tester

- Solutions

- Industries

- Success Stories

- Resources

- Company