Our comprehensive solution designed to revolutionize preventive maintenance for electric motors across diverse industries including automotive, aerospace, mobility, rail, maritime, logistics, water, wind and solar sectors. Our cutting-edge platform employs advanced algorithms and predictive analytics to continuously monitor the health and performance of electric motors, ensuring optimal functionality and reducing the risk of unexpected downtime.

With real-time alerts and notifications, users can proactively address potential issues before they escalate, thus maximizing efficiency and prolonging the lifespan of critical equipment. Whether you operate a fleet of vehicles, manage aircraft motors, oversee railway locomotives, or maintain maritime vessels, our intuitive solution provides invaluable insights to streamline maintenance operations and enhance overall reliability. Join us in embracing the future of electric motor maintenance with precision, efficiency, and peace of mind.

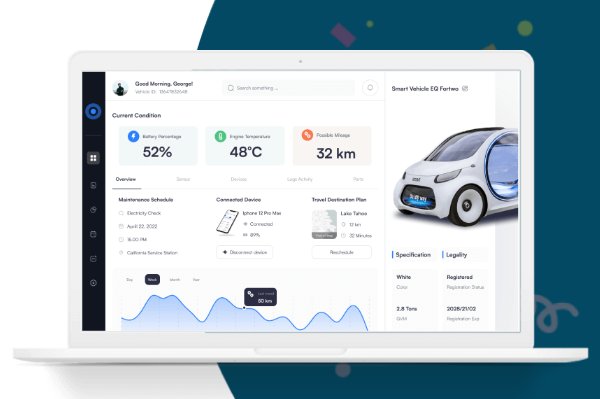

The system includes a very user-friendly software, presenting the data in graphs and tables, and saving them for evaluation, comparison, quality assurance.

Our comprehensive solution designed to revolutionize preventive maintenance for electric motors across diverse industries including automotive, aerospace, mobility, rail, maritime, logistics, water, wind and solar sectors. Our cutting-edge platform employs advanced algorithms and predictive analytics to continuously monitor the health and performance of electric motors, ensuring optimal functionality and reducing the risk of unexpected downtime.

With real-time alerts and notifications, users can proactively address potential issues before they escalate, thus maximizing efficiency and prolonging the lifespan of critical equipment. Whether you operate a fleet of vehicles, manage aircraft motors, oversee railway locomotives, or maintain maritime vessels, our intuitive solution provides invaluable insights to streamline maintenance operations and enhance overall reliability. Join us in embracing the future of electric motor maintenance with precision, efficiency, and peace of mind.

The system includes a very user-friendly software, presenting the data in graphs and tables, and saving them for evaluation, comparison, quality assurance.

Sensor Installation

High-resolution sensors are deployed on motors and rotating machines, even in harsh, remote, or hard-to-reach locations. These sensors capture live performance data across multiple physical variables.

Secure Data Transmission

Collected data is securely transferred to the cloud using encrypted communication channels to maintain confidentiality and data integrity.

AI-Based Data Analysis

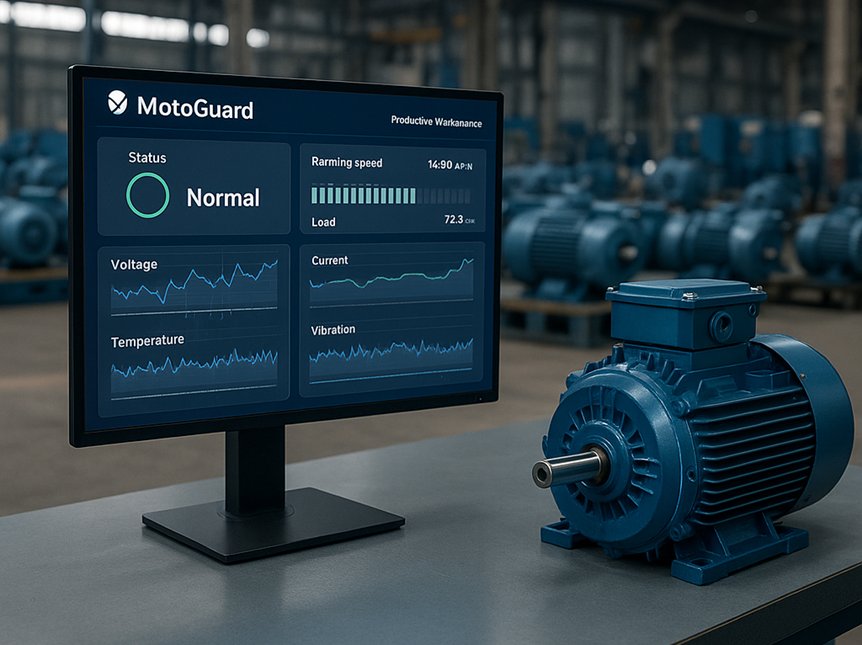

Using advanced machine learning algorithms, MotoGuard detects deviations, develops health trends, and identifies potential faults. The system establishes baseline conditions for each motor and updates them continuously for improved accuracy.

Prescriptive Insights Generation

MotoGuard doesn’t just alert you when a motor is behaving abnormally — it diagnoses the probable cause and provides prescriptive recommendations for corrective action.

Real-Time Dashboards and Alerts

All insights are accessible through an intuitive, mobile-friendly dashboard, offering live status monitoring and detailed reports.

Users receive clear status indicators — Green (Normal), Yellow (Alert), Orange (Warning), Red (Alarm) — based on defined limits.

What MotoGuard Monitors and Measures

Ready to elevate your motor testing and predictive maintenance strategies? We're here to help. Whether you have questions about our solutions, need personalized advice, or want to explore partnership opportunities, we're just a message away. Connect with us today to unlock the full potential of your operations and drive success in the world of motor testing and predictive maintenance. Let's innovate together!

Thank you for your submission! Your brochure is on the way!

Thank you for your submission! Your brochure is on the way!