Experience unmatched performance, speed, and precision with Motomea’s Inertial Dynamometer System (IDS). Engineered with patented technology, the IDS delivers full-load performance analysis—from stall to no-load—without requiring external mechanical loading.

With advanced dynamic testing features, including ripple torque, cogging, and friction spectrum analysis, the IDS provides comprehensive insight into motor behavior under real-world acceleration and deceleration conditions. Ideal for R&D, Quality Assurance, and End-of-Line environments.

Purpose-built for reliability, high throughput, and integration into modern test labs, the IDS ensures data-rich, actionable diagnostics for every motor—every time.

As pioneers in motor testing technology and the inventors of the Inertial Dynamometer, Motomea has been delivering cutting-edge motor testing equipment for over 25 years. Our products are designed to accurately test, measure, and control torque, speed, and power across a wide range of electric motor applications.

We are a globally recognized leader in motor test equipment manufacturing, committed to developing innovative solutions that optimize efficiency and reduce costs. Our team of highly skilled engineers, spanning electrical, mechanical, electronic, and software disciplines—ensures that every product meets the highest technical standards, and also provide reliable clear output and perform well under rigorous and harsh environment conditions.

Motomea offers an extensive portfolio of advanced measurement and control solutions, supported by a global network of experienced sales representatives and technical service professionals.

Motomea offers tailored mechanical and electrical engineering solutions to meet specific customer needs, enhancing system performance. Our patented dynamic motor testing system analyzes motors and powertrains during acceleration and deceleration, ensuring comprehensive testing across a wide range of speeds and torques. Designed for modern e-drive systems, our optimized test systems are future-proof.

Motomea maintains ISO 9001:2015 quality management certification for all company sections, and products are built to complete turnkey systems

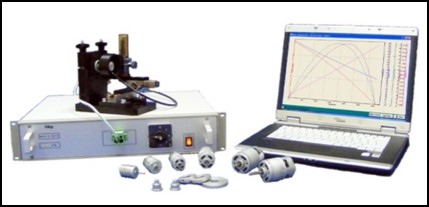

Inertial Dynamometer

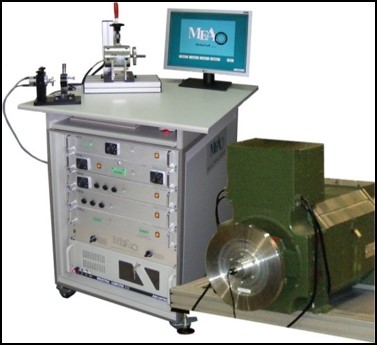

Traditional Dynamometer

Very simple test procedure

More complex test procedure

Fast results (a few seconds)

Long test cycle time

Does not require any complicated mechanical coupling nor any adjustment

Requires additional complex and accurate coupling

Applicable for Quality Control, R&D, and End of Line

Applicable for Quality Control, R&D

No need for previous skills

Requires know-how and expertise

A simple and generic holding device, supplied with the system

Requires additional complex and heavy-duty holding device

Thank you for your submission! Your brochure is on the way!

Thank you for your submission! Your brochure is on the way!