Motomea delivers advanced testing solutions for the entire spectrum of electric vehicles (EVs). Our chassis dynamometers simulate real-world road conditions and ensure vehicles meet quality, safety, and compliance standards.

Whether you're an importer validating performance, an R&D center verifying compliance, or a manufacturer testing durability, Motomea delivers the performance insight you need.

What Is a Chassis Dynamometer?

Simulating the Road in the Lab

A chassis dynamometer (or “chassis dyno”) is a test platform that allows an entire electric vehicle to be tested in place. It simulates road conditions such as resistance, slope, and inertia while collecting real-time performance data.

Why It Matters:

Versatile Solutions For:

System Technology & Capabilities

EV Chassis Testing Suite

Supported Test Profiles:

Heavy-Duty Chassis Dynamometers

Built for Electric Trucks, Buses & Fleets

Motomea offers high-capacity dynamometers for testing commercial and municipal EV fleets under real-use conditions.

Key Features:

Motomea’s Chassis Dynamometer Systems

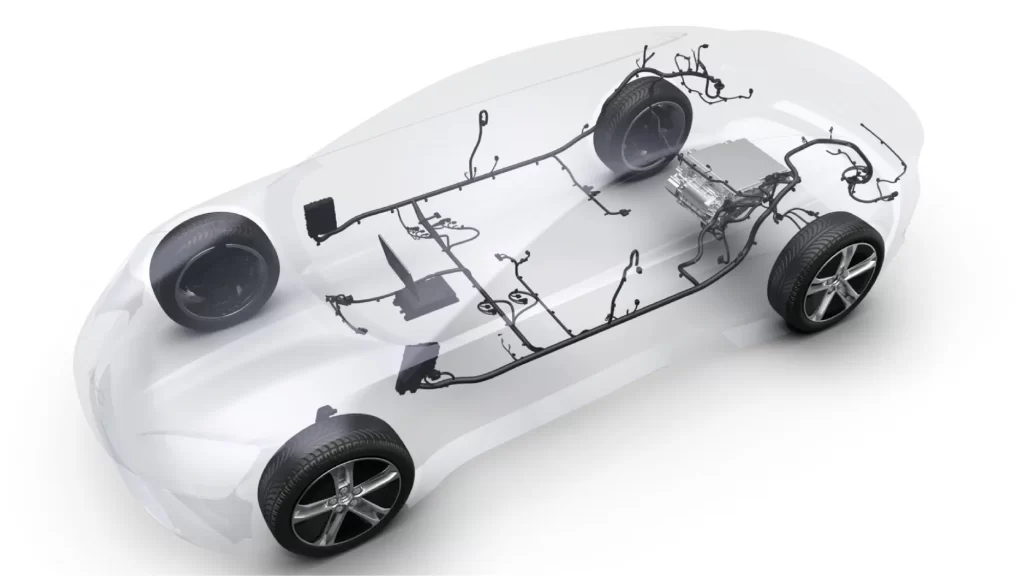

Engineered for precision, Motomea’s chassis dynamometers enable engineers to comprehensively assess how critical subsystems—such as the electric motor, battery pack, inverter, and drivetrain—interact under real-world load profiles. This evaluation is essential for ensuring regulatory compliance, validating powertrain integration, and achieving optimal vehicle performance across diverse operating conditions.

As an indispensable tool for EV manufacturers and R&D teams, the Motomea Chassis Dynamometer delivers high-fidelity testing of key performance parameters including power output, efficiency, torque, and speed. By replicating dynamic road load and drive cycle scenarios, it allows for in-depth analysis of energy consumption, control strategies, and thermal behavior. This insight is vital for optimizing the vehicle’s energy efficiency, functional safety, and system-level design—particularly in electric mobility platforms where precision and agility are paramount.

Ready to elevate your motor testing and predictive maintenance strategies? We're here to help. Whether you have questions about our solutions, need personalized advice, or want to explore partnership opportunities, we're just a message away. Connect with us today to unlock the full potential of your operations and drive success in the world of motor testing and predictive maintenance. Let's innovate together!

Thank you for your submission! Your brochure is on the way!

Thank you for your submission! Your brochure is on the way!